The Missouri Department of Natural Resources requires all facilities undergoing the antidegradation or construction permitting processes to evaluate a no-discharge wastewater treatment facility alternative. The Missouri Clean Water Law is intended to conserve, protect, maintain and improve the quality of Missouri’s waters. In addition, the goal of the federal Clean Water Act is eliminating all discharges. Therefore, the department encourages wastewater treatment systems to achieve no-discharge.

Water quality standards and effluent limitations will only become more stringent in the future. While a no-discharge system may not be feasible for every wastewater system, it must be evaluated during the department’s antidegradation, construction permit and operating permit review processes.

Permitting

A common misperception is that a no-discharge wastewater treatment facility does not require an operating permit. However, a Missouri State Operating Permit is required for all systems that disperse more than 3,000 gallons per day into the soil within the same operating location. It is very important that the system operates correctly as a no-discharge system. Failure to do so is a violation of the Missouri Clean Water Law and may result in enforcement action. These operating permits contain reporting requirements and conditions to be met. Please read through the permit carefully.

Permit requirements include math calculations. To determine math calculations, the No-Discharge Operator Math guidance can help.

Master General Permit

Master general permits, as opposed to site-specific permits, are issued to multiple locations where activities are similar enough to be covered by a single set of requirements. Master general permit MO-G823000 is for no-discharge, private, domestic wastewater treatment facilities with design flows of less than 50,000 gallons per day. Refer to the Applicability section of MO-G823000 for more details.

Site Specific Permit

Most no-discharge MSOPs are site specific and reflect the unique site of the no-discharge facility and land application area.

Permit Exemption

- 3,000 Gallon Per Day or Less No-discharge Permit Exemption for Domestic Wastewater Design Guidance - PUB1319

- De Minimis Wastewater Permit Exemption - PUB2995

Discharge Facility Categories

No-discharge facilities may fall into one of three categories: regionalization, surface land application or subsurface soil dispersal systems. More details about each category and additional information is available below.

Regionalization

Regionalization can range from physically connecting to another wastewater system or consolidating two or more treatment facilities, to administrative solutions, such as cooperative purchasing, contract billing or shared operator employment. Physically connecting to another wastewater system reduces the number of discharges to waters of the state because only the discharging wastewater treatment facilities are required to have a Missouri State Operating Permit (MSOP).

Typically, regionalization decreases the operation and maintenance portion of user raters. Larger wastewater systems have greater technical, managerial and financial capabilities in general. This leads to quicker response during emergencies and a better position to finance capital improvement projects.

Barriers to regionalization include local opinion, geography and large upfront capital costs. Local issues could be improved upon with open communication with neighboring systems. In remote rural areas, the geographic distance between wastewater systems may be too great for a physical connection. In these instances, administrative solutions should be considered. Where physical connection or consolidation is assessed, large upfront capital construction costs are often necessary. The department's State Revolving Fund loan program awards additional priority points for regionalization projects. A low-interest State Revolving Fund loan could help finance construction projects. More information on the State Revolving Fund loan program can be found on the department's Wastewater Financial Assistance webpage.

Regionalization is a complex process and not feasible for every system, but it could be a cost-effective approach for some. In addition, a regional connection is a requirement in some MSOPs; 10 CSR 20-6.010(8)(A) requires a facility located within the service area of a Level 1, Level 2 or Level 3 Authority facility with an area-wide management plan to connect within the timeframe allotted by continuing authority with is notice of connection availability.

Surface Land Application

Surface Wastewater Irrigation

Surface Land Application

Surface land application is defined as the application of wastewater to the land surface at a controlled rate. Surface land application benefits the crop and soil, and eliminates a discharge to waters of the state. Below are the most common methods of surface land application in Missouri.

Center Pivot

A center pivot is a truss supported sprinkler system with a fixed central wastewater supply. The center pivot moves in a circle to irrigate 20 to greater than 400 acres. The center pivot is the most common land application method for high acreage sites with crop fields or hay. This option has a higher capital cost but is less labor intensive and offers efficient irrigation.

olid Set Sprinklers

Solid set sprinklers apply wastewater by means of permanently or semi-permanently installed sprinklers using a rotating nozzle. These sprinklers allow a high volume of wastewater to be applied. Harvesting a crop can be difficult to maneuver around these sprinklers so they are frequently used with hay.

Traveling Gun

Traveling gun systems are self-propelled, single large gun sprinkler units that are connected to the wastewater supply by a hose. Since the operator has to reposition the traveling gun after each pass, this system is more labor intensive.

Operation and Maintenance

Surface land application should occur whenever weather and soil conditions are suitable, while adhering to the application rates listed in the MSOP. These application events should occur during the daylight hours unless a nighttime plan is approved by the department. The wastewater treatment facility should maintain the storage basins in good operational condition, including but not limited to: mowing, removing any woody vegetation, sludge monitoring and removal, and maintaining any security features such as fences and lockable gates. Rodents, such as muskrats, will need to be eliminated and any damage sustained to the berms repaired as appropriate. Also, the operational control monitoring requirements in the Clean Water Commission Treatment Plant Operations, 10 CSR 20-9, must be performed as well as any MSOP specific monitoring.

Subsurface

Subsurface Soil Dispersal Systems

Subsurface soil dispersal is the method of distributing effluent uniformly into an unsaturated (vadose) zone within the soil allowing for the effective treatment of bacteria and nutrients along with the local reuse of the treated water. A sustainable management plan must be devised and followed to ensure any subsurface soil dispersal system is sustainable, protective of public and the environment.

Subsurface soil dispersal systems can overcome a number of soil and site limitations and should be included among alternatives evaluated when planning a new wastewater system or upgrading an existing system. Several different approaches have proven successful in the design, operation and maintenance of large-scale subsurface soil dispersal systems. The subsurface soil dispersal systems described below are for domestic wastewater (sewage) only, defined in RSMo 701.025(12) as “Human excreta and wastewater, including bath and toilet waste, residential laundry waste, residential kitchen waste and other similar waste from household or establishment appurtenances.”

Regardless of the system chosen, the design engineer is responsible for properly assessing and documenting that the selected system will work in a specific location, under the specific soil and site conditions present, while ensuring the entire system is sustainable and protective of the environment and public health.

Conventional

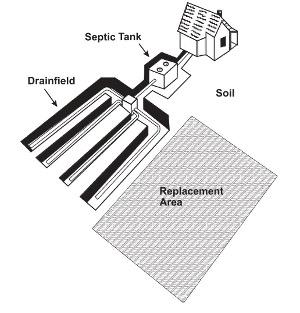

Source: EPA’s Onsite Wastewater Treatment Systems Manual, 2002

Conventional subsurface application includes the collection system, followed by a septic tank and then flows by gravity to a drain field for ultimate dispersal. Conventional subsurface systems in the past have been referred to as “septic systems” but the septic system is just a component of the overall treatment system. This option works well for single-family dwellings. Drawbacks to the conventional system include more land required for the drain field than with other subsurface methods, and issues with equal dispersal once the field has greater than 500 linear feet.

Low-Pressure Piping

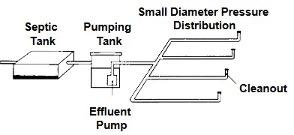

Decentralized Systems Technology Fact Sheet Low Pressure Pipe Systems, 1999

A low-pressure distribution system is a shallow, low pressure-dosed subsurface soil dispersal system with a network of small diameter perforated pipes placed about 10 to 12 inches deep in narrow trenches, commonly 12 to 18 inches wide, spaced 5 feet apart. The system also includes a dosing tank that holds the effluent and one or more pumps that deliver it to the lateral lines within the soil under relatively low pressure. These systems were developed to overcome shallow water tables and reduce anaerobic conditions (lack of oxygen) due to continuous soil saturation by undertreated effluent. This is usually done with timed dosing and alternating fields allowing effective use of the soil treatment area. The equal distribution of the effluent within a low-pressure distribution system allows for the sustainable use of the soil treatment area by enhancing the aerobic conditions and reducing the potential for the development of a restrictive biomat layer.

If there is sufficient soil treatment area available, a low-pressure distribution system can be scaled to accommodate flows in excess of 3,000 gallons per day (gpd). They can also accept wastewater that has only gone through anaerobic treatment with the separation of liquid and solids from a lagoon or septic tank. To enhance the life of the system, secondary (aerobic) treatment is strongly recommended for any system even if it is just serving a single family home.

Some of the limitations with low-pressure distribution systems are soils with shallow water tables or limiting layers, steep slopes, and limited available area. The potential for clogging the lateral line holes with solids or roots is also a shortcoming, along with limited storage capacity around the laterals. While a low-pressure distribution system can function in a variety of climate conditions, protection from freezing temperatures for certain components must be provided.

Drip

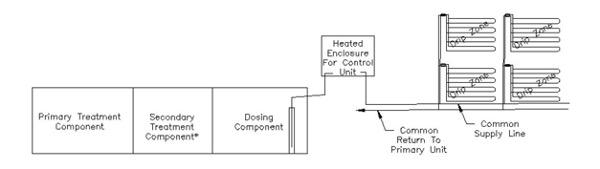

Iowa DNR Dispersal Systems Technology Assessment and Design Guidance, August 2007

Drip is a method of dispersing effluent from a domestic wastewater treatment facility into the subsurface soil using polyethylene tubing with an approximate diameter of one-half inch with emitters manufactured into it every 2 feet. Depending upon the soils, landscape position and other site conditions, the tubing is usually installed between 6 and 12 inches below the soil surface on 2-foot centers. The drip system also includes a dosing tank where the effluent is held until one or more pumps deliver it under pressure to the drip tubing installed in the soil. This is usually done with timed dosing and alternating fields, allowing effective use of smaller soil treatment area. Like a low-pressure distribution system, a drip system can receive anaerobically treated effluent, although that practice is discouraged for large-scale systems.

Drip systems can be scaled to accommodate large flows in excess of 3,000 gpd in a variety of soil and site conditions. The flexibility in geometry, design, construction and the ability to distribute effluent uniformly allows the drip tubing to be installed in wooded areas; on steep slopes; in soils with high water tables or a limiting layer; and in areas where the depth to bedrock is limiting. Drip systems have the potential to be used in higher risk areas near sensitive water bodies that were previously unsuitable for wastewater treatment systems.

While drip systems can overcome a considerable number of limitations, it is essential the components and soil treatment area are protected from livestock and heavy use. A sustainable management plan should be devised and followed to ensure that the system is sustainable. Also, while a drip system can function in a variety of climate conditions, protection from freezing temperatures for some of the components should be provided.

Certain developments need approval from the department for the method of wastewater disposal to install on-site wastewater treatment. Developments must receive approval from the department if the proposal has seven or more lots where each of those lots are less than five acres in size and use individual single-family on-site wastewater systems. The department must also approve any expansion of an existing subdivision by three or more lots, where each of those lots is less than five acres in size. Refer to the On-site Waste Disposal in a Subdivision Fact Sheet - PUB 2226 and 10 CSR 20-6.030 Disposal of Wastewater in Residential Housing Developments for more information

Mound

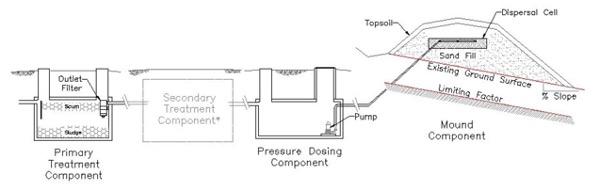

Iowa DNR Sand Mound Technology Assessment and Design Guidance, August 2007

The mound is the treatment and dispersal component of a complete on-site wastewater treatment system. Major components of the mound system are the primary treatment septic tank, the pressure dosing component and the optional, but recommended secondary treatment component to further treat the wastewater. Following the treatment in the primary and secondary treatment components, the water is dosed into the mound system.

The soil is the ultimate receiver of the wastewater and the most important part of the mound component. It is also the most variable and must be carefully evaluated. The discharged wastewater moves through the soil vertically and/or horizontally and must remain underground. Mound systems are designed to overcome site limitations, such as slow or fast permeability soils, shallow soil cover and a high water table.

Notification to the Missouri Geological Survey

When applying for the State Operating permit from the department for a subsurface dispersal system, the consulting engineering must notify the Missouri Geological Survey, which manages the Underground Injection Control Program, an inventory of underground injection wells located within Missouri.

Subsurface soil dispersal systems are considered class V underground injection control wells when they either receive domestic wastewater from two or more family residences or from a nonresidential establishment (schools, offices, shopping malls, etc.) when the system has a design capacity to serve 20 or more people per day. The purpose of the inventory is to maintain an accurate list of class V underground injection control wells permitted in Missouri; there are no other requirements.

Operation and Maintenance

Operations and Maintenance is a crucial component of subsurface systems working. An Operation and Maintenance manual should include a detailed discussion of the operation, controls, site and equipment maintenance, expected dosage rate, sampling and analysis, trouble shooting, chemicals management, personnel records, reporting, safety and emergency response procedures. The manual should be maintained and updated regularly, be available on site, and submitted to the department when requested.

Geohydrologic Evaluation

The objective of a geohydrologic evaluation is to examine site-specific geologic and hydrologic conditions and determine the potential impacts to groundwater. The Missouri Geological Survey also determines whether a stream is considered gaining or losing. These evaluations are required for new and modified earthen basins and surface and subsurface land application sites. Refer to 10 CSR 20-8.110(5)(E)6.G. – 3., 10 CSR 20-8.200(2)(B), 10 CSR 20-6.010(4)(A)5.D., and 10 CSR 20-6.010(7)(B)1.D..

Earthen basins shall not be located in areas receiving a severe collapse potential rating. Earthen basin structures located in areas receiving a severe overall geologic limitation rating or a moderate collapse potential rating with an appropriate engineering solution are reviewed on a case-by-case basis. Severe overall geological collapse potential ratings are more common in southwest Missouri which has karst features. Karst features are underlain by highly permeable soils and bedrock and are susceptible to contamination from the surface and the formation of sinkholes.

Soils Report

A soils report is required for all proposed subsurface soil dispersal systems to determine the soils loading rate. Additionally, a soils report is required for proposed surface land application systems desiring to land apply greater than 24 inches per year. A qualified individual must conduct the soils evaluation and prepare the report. This individual must have successfully completed 15 semester credit hours of soil science course work, including at least three hours of course work in soil morphology and interpretations. Refer to 10 CSR 20-8.110(7) and 10 CSR 20-8.200(2)(C).

The soils report can be generated only after a thorough, systematic investigation of the soil properties and landscapes of the proposed soil treatment area(s) has been conducted. Soil observation pits (backhoe or hand dug) must be dug to a depth to reveal the major soil horizons. The number of observation pits should be sufficient to adequately represent the primary and reserve soil treatment area and may be supplemented with soil borings to help determine the extent of similar soil properties. Detailed soil profile descriptions for each observation pit shall be submitted as described in the Soil Survey Manual. The soils report will also contain a map that clearly delineates the extent of the soil treatment area (primary & reserve), different soils and landscapes within the soil treatment area, observation pits (numbered), supplemental borings, existing or proposed dwellings and structures, public and private wells, abandoned wells, geothermal systems, sinkholes, existing and proposed easements, natural drainages, known and proposed utilities, and any other soil and site characteristics that could influence the soil's ability to effectively treat the effluent. A copy of the U.S. Geological Survey topographic map and U.S. Department of Agriculture County Soil Survey must be provided with the soil treatment area clearly delineated. The soils report shall provide an application loading rate for each different type of soil present and/or zone of treatment.

The report should include a conclusion summarizing the results and shall be signed and dated by the individual responsible for the documentation contained within it.

Popular Links

Navigation

- How's the Water

- Alerts or Water Hazards

-

Business, Industry and Other Entities

- Agriculture and Landowners

- Certified Laboratories

- Clean Water Compliance and Enforcement

- Permits, Certification, Engineering

- Professional Certifications and Training

- Technical Assistance and Guidance

- Water Reporting

- Water-related Fees

- Water-related Sites of Interest

- Water-related Variances

- Water Guidance and Technical Assistance

- Water Data and e-Services

- Water Financial Assistance Opportunities

- What We're Doing

- Get Involved

Contact Information

Water Pollution Control Branch

Water Protection Program

P.O. Box 176

Jefferson City, MO 65101-0176

United States