Vapors emitted by gasoline contain high levels of volatile organic compounds. When mixed with sunlight and heat, these pollutants aid in the formation of ground-level ozone. While effective in protecting Earth in the stratosphere, ozone is harmful to humans, animals and vegetation at the Earth’s surface. For more information regarding ground-level ozone and its effects, visit EPA's Ozone Good Up High, Bad Nearby webpage.

Capturing gasoline vapors during loading and refueling prevents the release of these vapors into the atmosphere. This is known as vapor recovery. Two different kinds of vapor recovery exist: Stage I and Stage II. Only Stage I vapor recovery is used in Missouri.

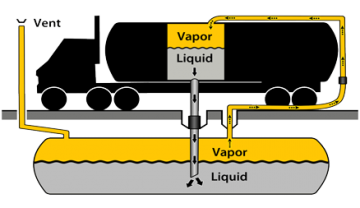

Stage I vapor recovery controls the release of gasoline vapors when tanker trucks receive or deliver gasoline. In the above image, black arrows represent gasoline flowing into a gasoline storage tank while orange arrows represent vapors forced from the tank back into the truck. The truck takes these vapors back to the terminal where they are burned off or condensed back into gasoline. Note that the tanker truck fills the gasoline storage tank at the bottom of the tank to further minimize gasoline vapor emissions by eliminating splashing and turbulence.

Stage I vapor recovery also controls the release of gasoline vapors from storage tanks at bulk plants and terminals.

EPA created an informational video describing Stage I gasoline filling requirements according to federal regulations; it does an excellent job of illustrating components of a typical Stage I system.

Vapor Recovery in Missouri

Vapor recovery programs regulate the release of gasoline vapors from various activities into the atmosphere. Vapor recovery programs in Missouri are key components of the state implementation plans (SIPs) that the department has with the U.S. Environmental Protection Agency designed to manage ozone concentrations in the St. Louis and the Kansas City areas.

Vapor recovery is also required at many stations outside the Kansas City and St. Louis areas due to promulgation of federal maximum achievable control technology standards. See below for more information about these federal standards.

Stage I Vapor Recovery at Gasoline Dispensing Facilities - Kansas City Area (Clay, Jackson and Platte counties)

Unless otherwise exempt, owners/operators of gasoline storage tanks in the Kansas City area are regulated by 10 CSR 10-2.260. An amendment to 10 CSR 10-2.260 “Control of Emissions During Petroleum Liquid Storage, Loading and Transfer” became effective Feb. 28, 2019. To view the amended language Secretary of State's website. Under the amended regulation:

- Subject gasoline storage tanks greater than 550 gallons and less than 40,000 gallons in the Kansas City area are required to have California Air Resources Board or department approved pressure/vacuum valves installed on all tank vents,

- Subject gasoline storage tanks greater than 2,000 gallons are required to be equipped with a vapor recovery system that demonstrates 90 percent collection efficiency. Owners/operators must pass a pressure decay test on all Stage I vapor recovery systems upon installation and again every six years. Additionally, owners/operators must pass a pressure/vacuum valve test at the time of installation and every three years thereafter.

Also visit Gasoline Dispensing Facilities for more information regarding the amendment.

Stage I Vapor Recovery at Gasoline Dispensing Facilities - St. Louis Area (Franklin, Jefferson, St. Charles and St. Louis counties and the City of St. Louis)

Unless otherwise exempt, owners/operators of gasoline storage tanks in the St. Louis area are regulated by 10 CSR 10-5.220. An amendment to 10 CSR 10-5.220, "Control of Emissions During Petroleum Liquid Storage, Loading and Transfer" became effective March 30, 2019. To view the amended regulation, visit the Secretary of State's website.

Under the amended regulation:

- Subject gasoline storage tanks with a capacity greater than 550 gallons and less than or equal to 1,000 gallons are required to have California Air Resources Board or department approved pressure/vacuum valves installed on all tank vents.

- Subject gasoline storage tanks with a capacity greater than 1,000 gallons and less than 40,000 gallons must have a Stage I vapor recovery system that demonstrates 98 percent collection efficiency. Owners/operators must submit a notification prior to constructing/modifying a Stage I vapor recovery system. Complete replacements or new installations require testing after the project is complete. Additionally, owners/operators must pass a pressure decay test and pressure/vacuum valve test every three years.

Also visit Gasoline Dispensing Facilities for more information regarding the amendment.

Federal Regulations 40 CFR 63 Subparts BBBBBB (6B) and CCCCCC (6C)

These federal regulations are applicable to all Missouri terminals and bulk plants (6B) and to all gasoline dispensing facilities (6C). The St. Louis area is currently in compliance due to the SIP-required vapor recovery program. While most Kansas City stations in compliance with the state regulation were in compliance with this federal regulation, some may have required additional controls. The final compliance date for all sources was Jan. 10, 2011.

The state of Missouri has not adopted enforcement delegation for these regulations. Therefore, please direct any questions regarding these regulations to EPA Region 7. Basic information regarding 6B and 6C is located on EPA's National Emissions Standards for Hazardous Air Pollutants - Area Source Standards website.